Plasma cutting is one of the most effective ways to cut metal, but it often comes with a frustrating problem: dross. Dross is the leftover metal stuck to the edge of your cut, and it can ruin the finish or slow down your project. The good news? You can avoid it. In this 2025 guide, you’ll learn the most effective plasma cutting tips to reduce dross, adjust travel speed, and pick the right settings for clean cuts. We’ll also show you how to match amperage to metal thickness, choose the best consumables, and control air quality — all based on expert techniques used by professionals. If you want smoother results with your handheld plasma cutter, these simple tips will make a big difference.

Table of Contents

- 🔧 The Essentials of Good Plasma Cutting Air Supply

- ⚡ Matching Amperage to Metal Thickness

- ✍️ Preparing Your Cut: Marking and Using a Drag Tip

- 🚶♂️ Travel Speed: The Key to Clean Cuts

- 🛠️ Choosing the Right Consumables for Thicker Metals

- 🔪 Cutting 3/8 Inch and 1 Inch Plate: Tips and Tricks

- 💡 Final Tips for Plasma Cutting Success

- ❓ Frequently Asked Questions

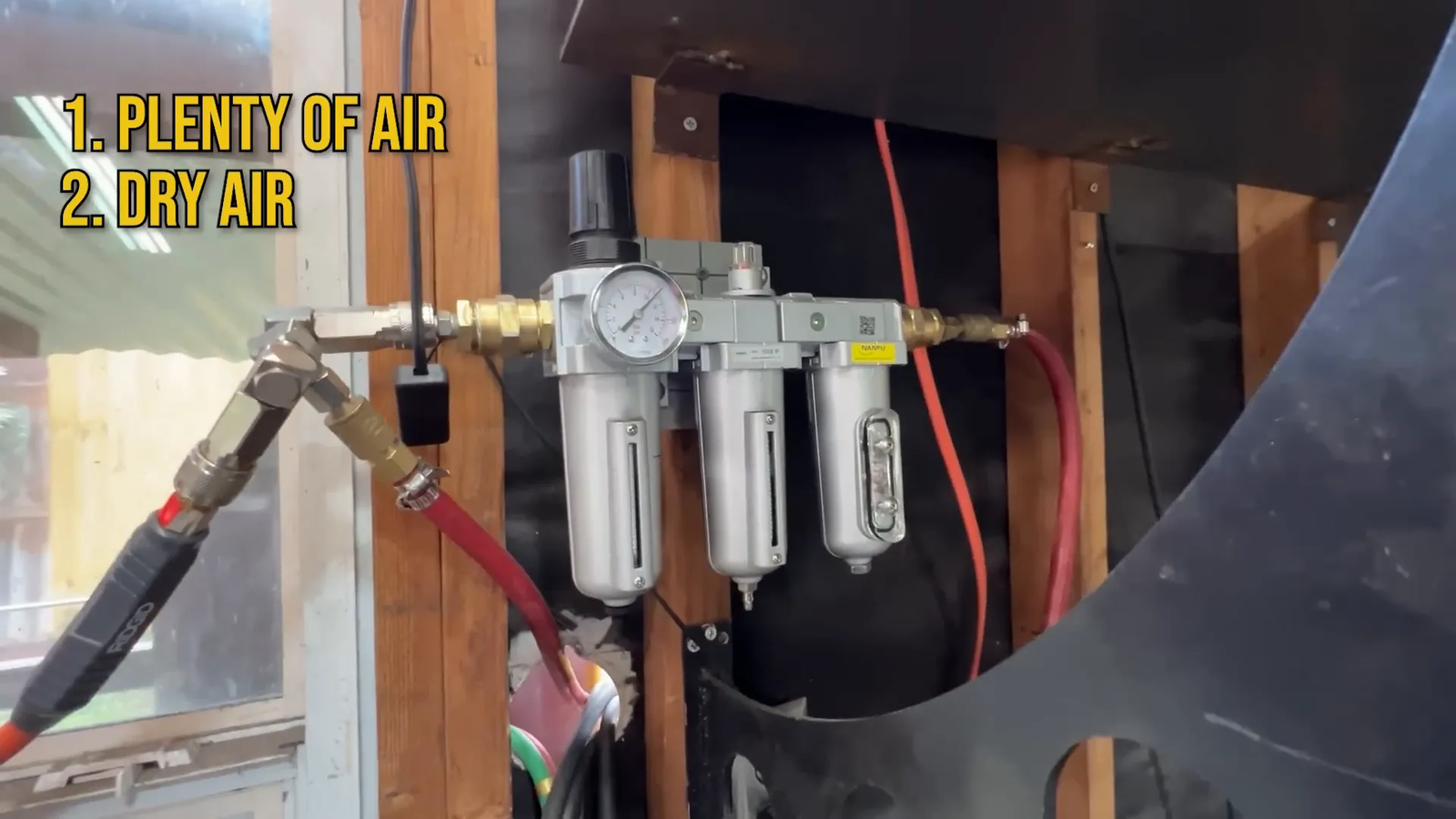

🔧 The Essentials of Good Plasma Cutting Air Supply

One of the foundational elements for a clean plasma cut is having good, dry air. Simply put, you need a lot of air — and it needs to be clean and dry. Using a compressor with a dry air filter is crucial, especially in humid environments like Houston, where moisture in the air can quickly damage your consumables.

Dirty or humid air not only shortens the life of your consumables but also negatively affects cut quality. So, ensure your air supply is filtered and dry to maintain consistent cutting performance and prolong consumable life.

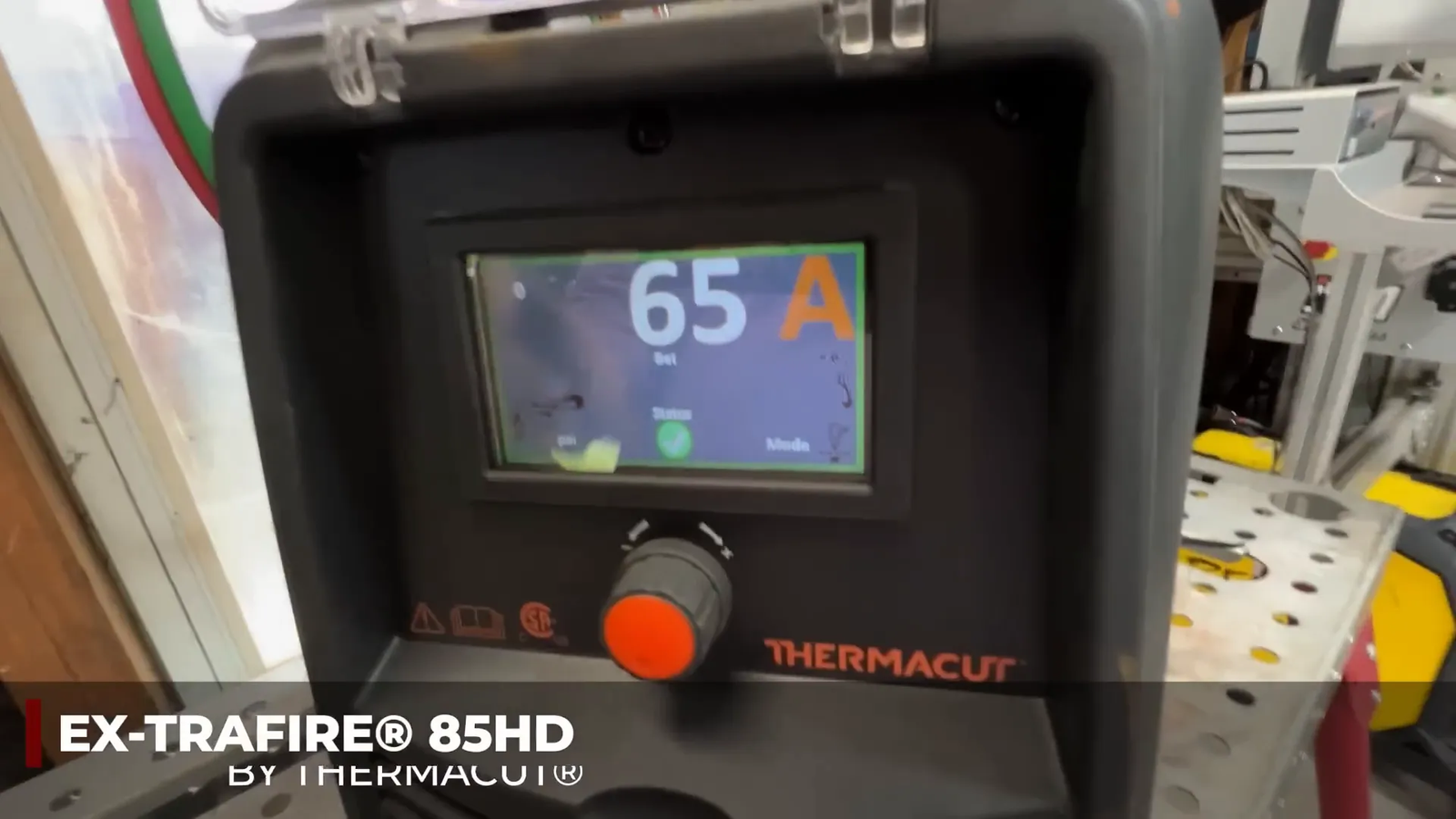

⚡ Matching Amperage to Metal Thickness

Setting the right amperage is key to getting clean cuts with your plasma cutter. The thicker the metal, the more power you need.

For example:

-

16-gauge and 10-gauge sheet metal require lower amperage.

-

3/8-inch and 1-inch steel plates need higher amperage to cut through effectively.

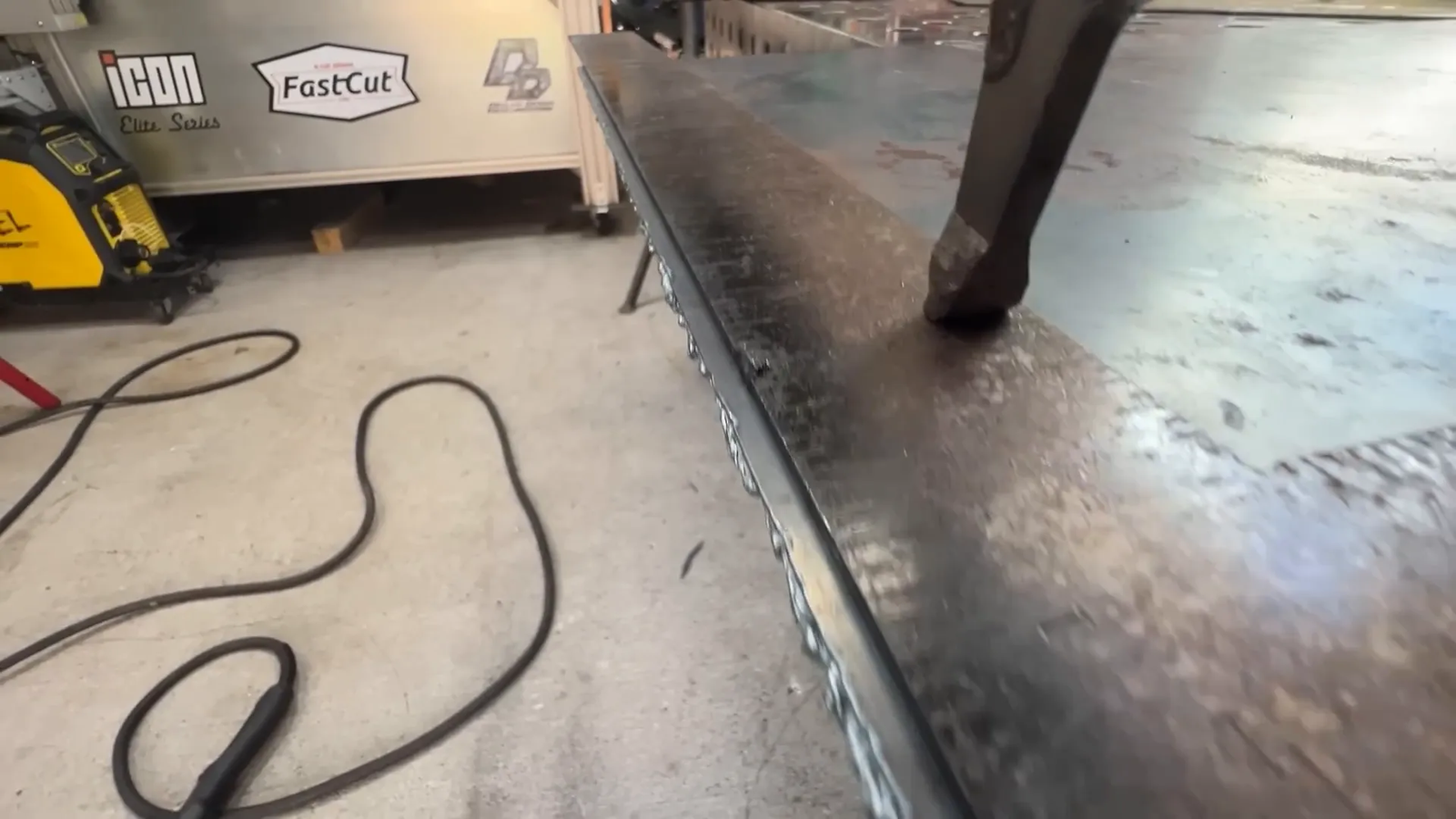

In professional setups, like the one shown on Weld.com, a Thermocut Xtrafire 85 HD is used. It runs on single-phase power and can cleanly cut up to 1-inch thick metal. If you have access to three-phase power, you can cut even thicker materials more efficiently.

👉 Need help choosing the right machine? Visit our full review of the Best Plasma Cutters of 2025 for expert picks based on power, features, and reliability.

✍️ Preparing Your Cut: Marking and Using a Drag Tip

Before starting, it’s helpful to scribe a line on your metal to guide your cut. This simple step makes following your cut path easier and more accurate.

For straight cuts, a drag tip with a fence can help maintain a consistent line. While some fabricators might cringe at using a worn-out square as a fence, it can still produce square cuts effectively. The key is to keep the torch flat and square to the metal surface to avoid the arc wandering.

🚶♂️ Travel Speed: The Key to Clean Cuts

Travel speed is one of the most critical factors for good plasma cutting. Moving too slowly causes excessive dross buildup, while moving too fast can cause the arc to wander or even pull out of the cut.

For 16 gauge metal, cutting too slowly results in a rough, dross-heavy edge. Increasing your speed significantly cleans up the cut, leaving almost no dross behind. The general rule of thumb: move as fast as your torch and material allow.

When moving to 10 gauge, which is roughly twice as thick as 16 gauge, you will need to reduce your travel speed accordingly. Watch the plasma tail coming out of the bottom of the cut; if it starts to curve, you’re moving too fast. Adjust your speed to keep that plasma tail straight for the cleanest cut.

🛠️ Choosing the Right Consumables for Thicker Metals

As you move into thicker metals like 3/8 inch plate, the choice of consumables becomes more critical. While drag tips work well for straight cuts with a fence, machine tips allow you to see the cut better and can be used for freehand cutting with more control.

For example, electrodes rated from 45 to 105 amps are versatile for various thicknesses, but it’s important to match your electrode and nozzle to your amperage setting. Using a 65 amp electrode with a 65 amp nozzle will give you a more precise cut and reduce arc wandering.

Note that nozzle orifice size affects the kerf width—the amount of material removed by the cut. Using a nozzle rated for higher amperage than your machine can supply causes the arc to wander and results in poor cut quality.

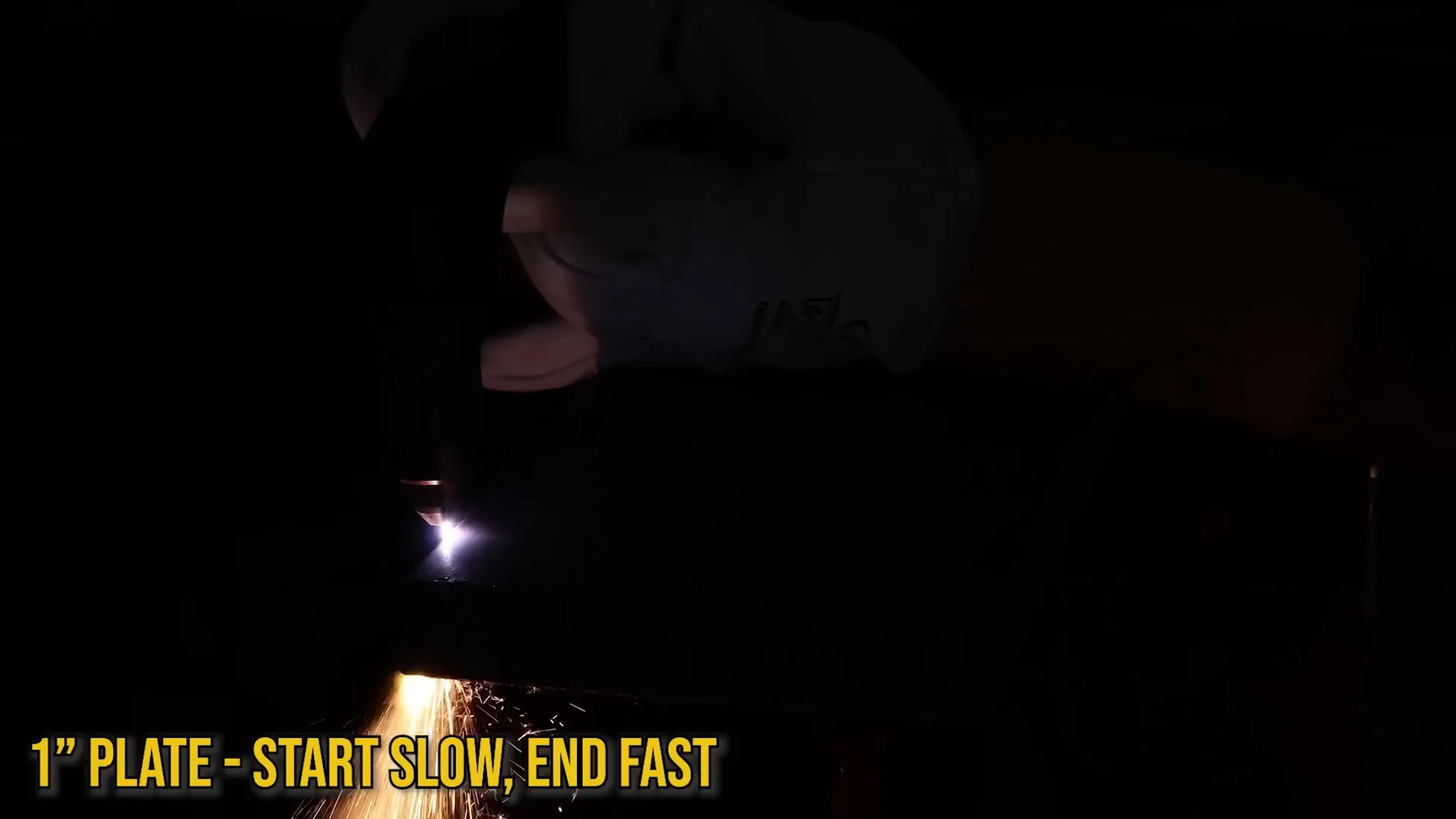

🔪 Cutting 3/8 Inch and 1 Inch Plate: Tips and Tricks

When cutting 3/8 inch plate, maintaining a straight, square torch angle is crucial. If your machine doesn’t have enough amperage for thicker metal, you can compensate by slightly angling the torch (about 10-15 degrees) to push the cut rather than dragging it. Dragging often causes the arc to jump out and results in uneven cuts.

For 1-inch thick plate, slow your travel speed significantly. Even then, you might see the arc tailing off or bouncing out when you speed up too much. Cutting thick metal reveals imperfections in technique, such as not holding the torch square, which leads to uneven cuts and excess dross.

One common mistake is using an 85 amp nozzle with a 65 amp machine. The larger orifice introduces too much arc wander, making it almost impossible to cut straight regardless of your speed.

💡 Final Tips for Plasma Cutting Success

- Max out your machine’s amperage and then adjust your travel speed for the best results.

- For thin sheet metal, cut fast, hot, and clean—don’t hold back.

- For thicker metals, fine-tune your amperage, consumables, and torch angle.

- Always keep your torch square to the workpiece or use a slight push angle if necessary.

- Use dry, filtered air to protect consumables and improve cut quality.

- Don’t use mismatched consumables; match your nozzle and electrode to your machine’s amperage.

With these tips, you can significantly reduce dross buildup and achieve cleaner plasma cuts, whether you’re working by hand or on a CNC table.

❓ Frequently Asked Questions

What causes excessive dross in plasma cutting?

Excessive dross is usually caused by cutting too slowly, insufficient amperage, or using the wrong consumables. Ensuring dry, clean air and proper travel speed helps minimize dross.

How do I know if my plasma cutter has the right amperage for the metal thickness?

Check your plasma cutter’s specifications and match the amperage to the metal thickness. For example, 16 gauge requires less amperage than 1-inch thick plate. Using the right electrode and nozzle size is also essential.

Can I use a drag tip for all types of cuts?

Drag tips are great for straight cuts with a fence but can be challenging on thicker metals or freehand cuts. Machine tips allow better visibility and control for freehand cutting.

Why is dry air important for plasma cutting?

Dry air prevents moisture from damaging your consumables and improves cut quality. Moisture in the air can cause premature wear and inconsistent cuts.

What should I do if my plasma arc keeps wandering?

This often happens when the nozzle or electrode amperage rating doesn’t match the machine’s output. Using the correct consumables and maintaining a steady, square torch angle helps keep the arc stable.